Technical Information

Technical Information Power And Control Cables

Power And Control Cables Power Appendixes

Power Appendixes CABLING ; Tools , procedure , accessories , laying and handling

CABLING ; Tools , procedure , accessories , laying and handling Repair of Damage to Outer Sheath

Repair of Damage to Outer Sheath صفحه Repair of Damage to Outer Sheath

|

Outer Sheath of Polyvinvlchloride (PVC) and Polyethylene (PE) Dependant upon the degree of damage, the stressing of the cable sheath during installation in the ground on racks in ducts as well as the required voltage withstand of the sheath during corrosion protection testing If the material of the outer sheath cannot readily be determined and neither can the cable type be established from the markings and relevant VDE specifications then a flame test may be necessary to establish whether the sheath material is of PVC or of PE. |

|

|

|

|

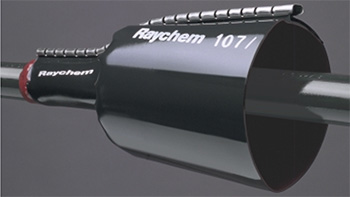

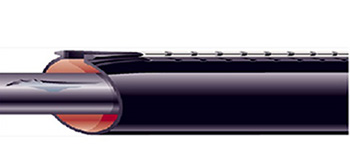

Repair with Shrink-On Sleeve A shrink-on sleeve, which is particularly easy to instal, comprises a longitudinally split shrinkable tube and this is recommended as a universal method of repair. This type of sleeve must be cut sufficiently long such that after being shrunk on to the cable it extends beyond the damaged part to each side by a distance of / = 3 x cable outer diameter with a minimum of 100 mm A longitudinal shrinking of some 10% must be allowed for. The damaged area of the cable sheath must be cleaned with solvent, corresponding to the length of the sleeve and roughened with emery cloth. The repair sleeve is then laid around the damaged portion and the press stud snap locking engaged . |

|

|

|